DI-N-OCTYL PHTHALATE (DOP) is a phthalate ester. It’s often used as a plasticizer in PVC products. It improves flexibility, making materials like plastic films and pipes more pliable.

Overview

Product name : DI-N-OCTYL PHTHALATE

CAS No. : 117-84-0

Molecular Formula : C24H38O4

EINECS NO. :204-214-7

DI-N-OCTYL PHTHALATE Properties

| Item | Excellent Grade  |  First Grade  | Qualified Grade  | Typical Value in Factory |

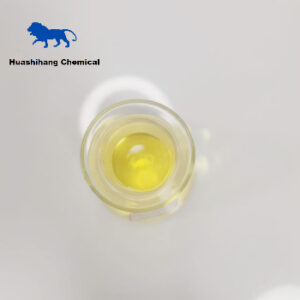

| Chromaticity (Platinum-Cobalt Number) | ≤ 30 | ≤ 40 | ≤ 60 | ≤ 30 |

| Purity | ≥ 99.5% | ≥ 99.0% | ≥ 99.0% | ≥ 99.5% |

| Density at 20°C | 0.982 – 0.988g/cm³ | 0.982 – 0.988g/cm³ | 0.982 – 0.988g/cm³ | 0.982 – 0.988g/cm³ |

| Acidity (Calculated as Phthalic Acid) | ≤ 0.010% | ≤ 0.015% | ≤ 0.030% | ≤ 0.010% |

| Flash Point | ≥ 196°C | ≥ 192°C | ≥ 192°C | ≥ 196°C |

| Moisture Content | ≤ 0.10% | ≤ 0.15% | ≤ 0.15% | ≤ 0.10% |

DI-N-OCTYL PHTHALATE Use

- Plasticizer in PVC: DOP is primarily used as a plasticizer in polyvinyl chloride (PVC) production. It enhances the flexibility, softness, and workability of PVC materials. This makes PVC suitable for a wide range of products such as plastic films for packaging (food packaging, industrial packaging), PVC pipes (for non-potable water systems and drainage), vinyl flooring, and artificial leather for furniture and clothing.

- Rubber Industry: It can be used as a processing aid and softener in the rubber industry. It helps to improve the processability of rubber compounds, making them easier to mix, shape, and vulcanize. Additionally, it can enhance the low-temperature flexibility and durability of rubber products like seals, gaskets, and hoses.

- Adhesives and Sealants: DOP is incorporated into adhesives and sealants to improve their flexibility, adhesion properties, and resistance to various environmental factors. It can be found in products used for bonding different materials together in construction, automotive, and other industries.

- Paint and Coating: In paints and coatings, DOP acts as a plasticizer to improve the film-forming properties, flexibility, and durability of the coating. It helps prevent cracking and peeling of the paint film and can enhance the overall performance of the coating on different substrates.

- Printing Inks: It is used in printing inks to adjust the viscosity and drying properties, ensuring smooth printing and good adhesion of the ink to the printing substrate. This helps in achieving high-quality printed images and text.

About 80% to 90% of dioctyl phthalate (DOP) is used in the PVC industry. The rest is used in rubber, recycled plastics, lubricants, adhesives, coatings, polymer additives, printing ink softeners, capacitor oils, etc., and can also be used in polyvinyl acetate and polyvinylidene chloride.

DOP Application Examples:

Anti-fog agricultural PVC films, weather-resistant agricultural PVC films, cable compounds (insulation grade), transparent hoses, common artificial leathers, enamel toys, packaging materials, PVC gloves, wallpaper, etc.

Packaging

200kg/drum

Storage

Keep in cool and dry place, store in sealed containers. Shelf life:two years.