Overview

Product Name : Alkylsulfonic phenyl ester

Synonym : T50 petroleum ester

CAS No. : 91082-17-6

EINECS : 293-728-5

Molecular Formula : Rso2C6H5(R=C12H25—C18H37)

Alkylsulfonic phenyl ester Properties

| Item | Specification |

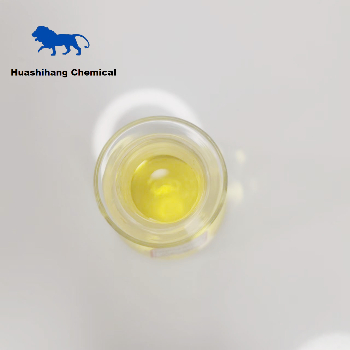

| Appearance | Yellowish transparent liquid |

| Refractive index | 1.490~1.500 |

| Acid value ( Mgkoh/g ) | ≤0.05 |

| Color ( Hazen ) | ≤700.00 |

| Density ( g/CM3 ) | 1.02~1.06 |

| Viscosity ( Mpa.S ) | 75.00~120.00 |

| Water | ≤0.05% |

| Flash point | 200.00~215.00℃ |

| Pour point | 32.00℃ |

| Boiling range | 211.00~279.00℃ |

| Saponification number | Only partial saponification possible |

Alkylsulfonic phenyl ester features

Catalysis

Some sulfonic acid derivatives are famous for their catalytic properties. They can be used as catalysts in various chemical reactions, including esterification reactions. Alkylsulfonic phenyl ester is an intermediates in the synthesis of various compounds.

Polymerization

Certain sulfonic acid derivatives has applications in polymerization reactions, contributing to the formation of specific polymers. Phenyl esters might be incorporated into polymer structures for desired properties. It can promote the excellent gel ability of most polymer materials including PVC and PU, reduce processing temperature, shorten processing time, greatly improve production efficiency and reduce energy consumption.

Good compatibility with PVC, PU, NR, SBR, SBR/BR, IIR, NBR, and CR.

Due to its technical structure, alkylsulfonate phenyl ester especially compared with DEHP, the advantage of resistance to saponification in contact with water and alkali metals is outstanding.

High weather resistance, excellent UV resistance.

Good electrical insulation and good weld ability.

Surfactants

Sulfonic acid derivatives are sometimes as produce surfactants. These compounds are materials in detergents, emulsifiers, and other products where surface activity is important. Alkylsulfonic phenyl ester may be part of the surfactant structure, influencing its properties.

Alkylsulfonic phenyl ester applications

Phenyl sulfonate is as a plasticizer in polyvinyl chloride (PVC), polyurethane (PU), natural rubber (NR), styrene-butadiene rubber (SBR), nitrile rubber (NBR) and chloroprene rubber (CR). It is PU-based sealing and bonding systems (one-component and two-component systems).

Glue : PVC type glue.

Cleaning : Alkylsulfonic phenyl ester is a cleaning agent for PU foaming machine.

Calendering

It also has use in leather film for automobile industry, tunnel inner wall and other industries, such as swimming pool cover, shower curtain, welding film, electrical insulation film

People also use Alkylsulfonic phenyl ester in slush plastic toys, PVC disposable gloves and other plastic dipped products.

Extrusion : Profiles for the automotive industry, fittings, pipe fittings, profiles of weather-resistant and alkali-resistant metals, and blown films

Injection molding : work shoes, industrial products

Coatings : it is a material in inflatable products, coatings for protective cloth, raincoats, bathroom mats, polyurethane waterproof coating and nitro paint.

Food : food contact items such as packaging film, food conveyor belt.

Packaging

Metal drum

Storage

Keep in cool and dry place, and store in sealed containers.

Instructions and Suggestions for Use

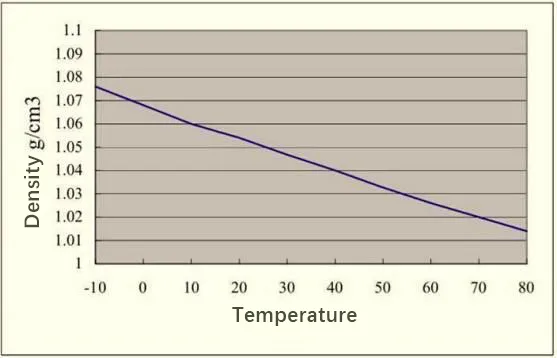

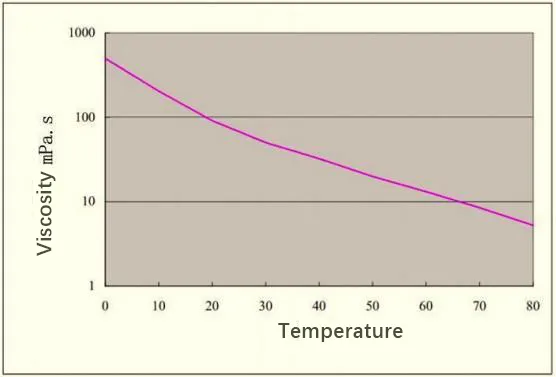

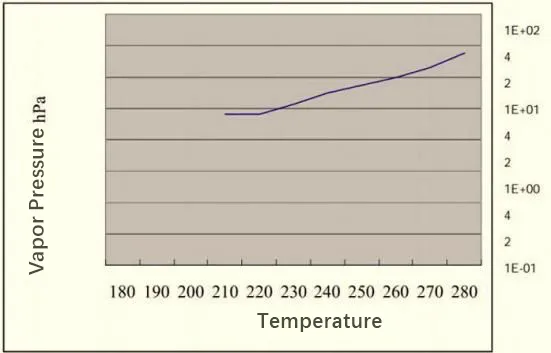

The design of storage tank and pipeline diameter and extraction pump are important parameters when measuring storage for density, viscosity and vapor pressure. Figures 1 through 3 present data on these properties for phenyl alkylsulfonates.