4-Hydroxy TEMPO Test method.

1.0 4-Hydroxy TEMPO Range

This standard specifies the requirements, test methods, inspection rules, marking, packaging, transportation and storage of 4-Hydroxy TEMPO.

This standard applies to the 4-Hydroxy TEMPO synthesized with tetramethylpiperidinol and hydrogen peroxide as the main raw materials.

Product Name: 4-Hydroxy TEMPO

Chemical name: 4-Hydroxy -2,2,6,6-Tetramethyl Piperidine, free radical

Other name: Inhibitor 701

CAS No.: 2226-96-2

Molecular Formula:C9H18NO2

2.0 4-Hydroxy TEMPO Normative references

The following documents are indispensable for the application of this document. For dated references, only the dated version

Applicable to this document. For undated references, the latest edition (including all amendments) applies to this document.

GB/T 617 chemical reagent melting point range determination method

GB/T 6283 Determination of moisture content in chemical products – Karl Fischer method GB/T 6679 Solid Chemical Products Sampling General

GB/T 7531 Determination of burning residues in organic chemical products

GB/T 10004 plastic composite film for packaging, bag dry composite, extrusion compound GB/T 14187 packaging container paper drum

JJF 1070 Quantitative Packaging Commodity Net Content Measurement Inspection Rules State Administration of Quality Supervision, Inspection and Quarantine, Order No. 75 of the Measures for the Supervision and Administration of Quantitative Packaging Commodities Measurement

3.0 4-Hydroxy TEMPO Requirements

3.1 Appearance quality

This product is orange-red crystalline powder or flake solid.

3.2 Quality indicators

The quality indicators shall comply with the requirements of Table 1.

| Item | Specification |

| Ethanol solubility | Clear |

| Assay(GC) | ≥99.00% |

| Water | ≤0.50% |

| Ash | ≤0.10% |

| Melting point | 69.0-72.0℃ |

3.3 Net content

It shall comply with the provisions of the Measures for the Supervision and Administration of Quantitative Packaging Commodities Measurement.

4.0 Test methods

4.1 Appearance

It was carried out by visual inspection.

4.2 Melting point

According to the method specified in GB/T 617.

4.3 Moisture

According to the method specified in GB/T 6283.

4.4 Ash

According to the method specified in GB/T 7531. The ignition temperature is 750 °C.

4.5 Purity

4.5.1Principle of the method

Under certain conditions, the sample to be tested is injected into the gas chromatograph gasification chamber with a micro-injector, and the sample is gasified and loaded.

The body enters the column, is separated by a chromatographic column, and is detected by a hydrogen flame detector. The detection result is analyzed and recorded in the chromatographic workstation.

Quantitative analysis by area normalization method was used to measure the content of 4-Hydroxy TEMPO..

4.5.2 Instruments, equipment, materials and reagents

a) Gas chromatograph: equipped with a hydrogen flame detector

b) Column: SE-30 capillary 30m × 0.25mm × 0.25μm

c) Sampler: 10 ul microsampler

d) Reagent: absolute ethanol (analytical grade)

4.5.3 Test conditions

a) carrier gas (high purity nitrogen) flow rate: 0.5ml / min – 1.0ml / min;

b) hydrogen flow rate is: 30ml / min;

c) air flow rate is: 300ml / min;

d) inlet temperature: 250 ° C;

e) Detector temperature: 280 ° C; 10 ° C / min

f) Temperature programmed conditions: initial temperature 80 ° C (for 1 min) 280 ° C (for 20 minutes)

4.5.4 Experimental steps

Put an appropriate amount of the sample into the test tube, add the absolute ethanol according to the ratio of the sample and the solvent anhydrous ethanol: 1:6

Mix and mix, take appropriate amount of sample (the amount of injection can be displayed on the spectrum to show all the peaks), the injection volume is 0.2ul.

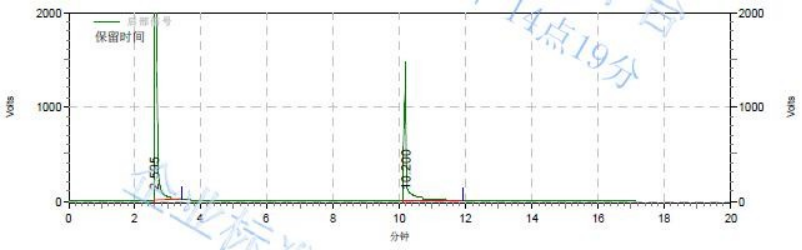

4.5.5 Spectral comparison

The spectrum comparison is shown in Figure 1 and Table 2.

Table 2: 4-Hydroxy TEMPO retention time

Compound Retention time

ethyl alcohol 2.6

4-Hydroxy TEMPO 10.2

Note: The above chromatographic operating conditions are typical, and the given operating parameters can be appropriately adjusted according to different instrument characteristics in order to obtain the best results.

4.5.6 Calculation of results

Calculated according to the normalization method in GB/T 9722.

4.6 Net content

According to the method specified in JJF 1070.

5.0 Inspection rules

5.1 Group batch and sampling

According to the provisions of GB/T 6679, the product is to be batched in 1 batch, sampled at 1%, and the sampling amount shall not be less than

100g.

5.2 Inspection

5.2.1 The product must pass the inspection by the quality inspection department of the company, and the certificate will be issued before leaving the factory.

5.2.2 The inspection items are the entire contents of Chapter 3.

5.3 Decision rules

When all the inspection items meet the requirements, it is judged as qualified. If any of the indicators are unqualified, the sample should be doubled for the unqualified item.

If the product is still unqualified, the product will be rejected.

6.0 Marking, packaging, transportation and storage

6.1 mark

A solid mark should be affixed to the packaging container and should indicate the following:

a) product name;

b) specifications;

c) net content, gross weight;

d) shelf life;

e) name of the manufacturer and site;

f) Production date or batch number.

6.2 Packaging

The inner packaging of the product is packed in plastic bags, and the outer packaging is cardboard drum or cardboard box, and the specification is 25kg/barrel (box). Its packaging bag should comply with the provisions of GB/T 10004, the packaging barrel should meet the requirements of GB/T 14187.

6.3 Transportation

The product should be kept away from light and sealed during transportation, and should not be wet. It should not be mixed or mixed with acid or alkaline substances.

6.4 Storage

6.4.1 The product should be stored in a ventilated, dry warehouse and protected from light.

6.4.2 Under the specified storage conditions, the product has a shelf life of one year from the date of manufacture.