Glyoxylic acid producing method: Glyoxal oxidation method

Glyoxylic acid has the properties of aldehyde and acid due to its containing aldehyde and carboxyl functional groups. The chemical properties are quite active. It is an important fine chemical raw material and intermediate. Glyoxlic acid is mainly used in fields such as spices, pharmaceuticals, pesticides, coatings, cosmetics, food additives, cleaning agents.

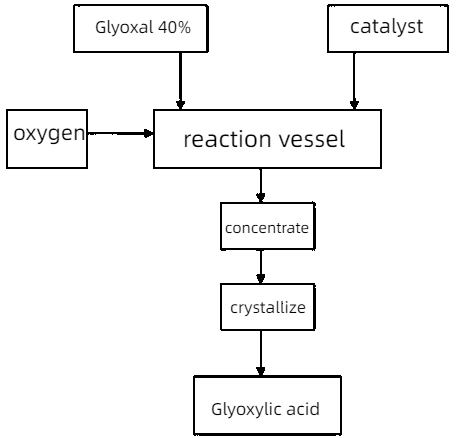

Glyoxal 40% solution and catalyst are used to prepare glyoxylic acid by pure oxygen method.

Below is following steps:

(1) Adding glyoxal solution and catalyst to the reactor respectively, then inlet xygen.

The mass ratio of glyoxal to catalyst is 0.8:1-1.2.

The catalysts are concentrated nitric acid and concentrated hydrochloric acid.

The molar ratio of concentrated nitric acid to concentrated hydrochloric acid is 0.6:1-1.2.

(2) Heating, controlling the reaction temperature to 40-45 ℃, pressure to 0.1-0.18MPa and reaction time to 1.5-2h;

(3) Control the reaction temperature to 80-85 ℃, pressure to 0.05-0.1MPa, and reaction time to 0.5-1h for concentration;

(4) Sampling the obtained solution and measuring the conversion of glyoxal to obtain the target glyoxal acid solution;

(5) Glyoxylic acid solution is crystallized.